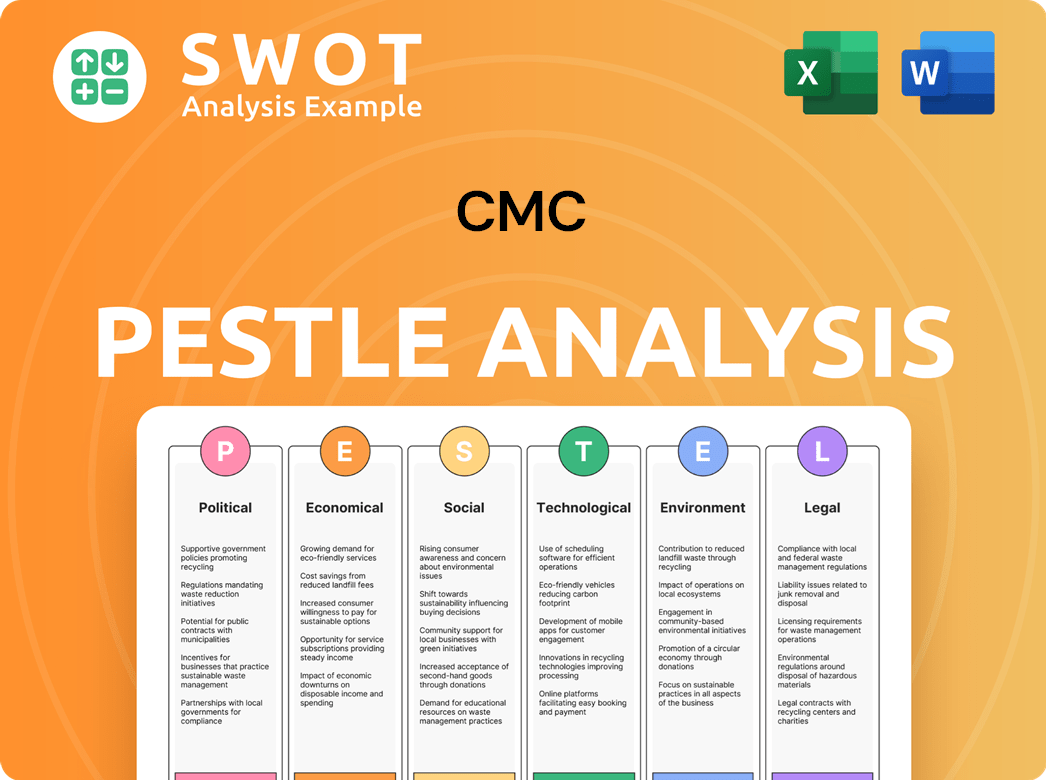

CMC PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

CMC Bundle

What is included in the product

Identifies how macro-factors uniquely shape the CMC, spanning Political, Economic, Social, etc.

Visually segmented by PESTLE categories, allowing for quick interpretation at a glance.

What You See Is What You Get

CMC PESTLE Analysis

We’re showing you the real product. This CMC PESTLE Analysis preview details key Political, Economic, Social, Technological, Legal, and Environmental factors. After purchase, you'll instantly receive this exact file.

PESTLE Analysis Template

CMC operates within a complex landscape, influenced by global events. Our PESTLE analysis offers a concise snapshot of these forces. We examine political stability, economic fluctuations, social trends, technological advancements, legal compliance, and environmental factors. These insights empower you to make informed decisions. Gain a competitive edge with our complete, in-depth analysis—available now!

Political factors

Government trade policies, including tariffs, directly influence CMC's operations. The U.S. has imposed tariffs on steel and aluminum, impacting raw material costs. This affects CMC's pricing strategies and competitiveness in the market. For instance, in 2024, steel tariffs added approximately 25% to import costs, affecting companies like CMC. These tariffs aim to protect domestic steel production, affecting the global market.

Government infrastructure spending, like the Infrastructure Investment and Jobs Act, boosts demand for steel and metal. CMC benefits from this through higher sales and government contracts. The U.S. government plans to invest $1.2 trillion in infrastructure. This includes $110 billion for roads, bridges, and major projects, directly impacting CMC. In 2024, infrastructure spending is projected to increase by 10%.

Geopolitical conflicts and trade restrictions significantly impact metal supply chains. For instance, the Russia-Ukraine war disrupted steel exports, causing price volatility. In 2024, global steel prices fluctuated due to these tensions, affecting companies like CMC. These disruptions can lead to higher costs and operational challenges.

Domestic Manufacturing Support

Government backing for domestic manufacturing significantly impacts CMC. Initiatives promoting local production, like the Build America, Buy America Act, are key. These policies can increase demand for CMC's steel products. In 2024, the U.S. government allocated $400 million for infrastructure projects prioritizing domestic materials.

- Increased demand for domestically produced steel.

- Support from government initiatives.

- Favorable business environment for CMC.

Regulatory Environment

Changes in regulations significantly impact CMC's operations. The company must adapt to evolving legal frameworks, affecting production costs and market access. Compliance with environmental standards and trade policies is crucial. For example, in 2024, environmental compliance costs for manufacturing firms rose by approximately 7%. These costs can affect profit margins and competitiveness.

- Compliance with evolving legal frameworks affects production costs.

- Environmental standards and trade policies are crucial for market access.

- Manufacturing firms saw a 7% increase in compliance costs in 2024.

Government trade policies influence CMC, with tariffs impacting raw material costs and market competitiveness. Infrastructure spending, such as the Infrastructure Investment and Jobs Act, boosts demand. Geopolitical conflicts and trade restrictions cause supply chain disruptions and price volatility, impacting operations.

| Political Factor | Impact on CMC | 2024/2025 Data |

|---|---|---|

| Trade Policies (Tariffs) | Affects raw material costs, competitiveness | Steel tariffs add 25% to import costs, Q1 2024. Projected trade policy changes. |

| Infrastructure Spending | Boosts demand, higher sales, and contracts. | $1.2 trillion infrastructure investment. 10% increase in spending expected in 2024. |

| Geopolitical Conflicts | Disrupts supply chains, price volatility. | Global steel prices fluctuated; disruptions in 2024 affected CMC. |

Economic factors

The construction market's vigor heavily impacts CMC's demand for steel and metal. Interest rates, construction levels, and infrastructure projects are crucial. In Q1 2024, U.S. construction spending hit $2.09 trillion, a 10.7% rise from Q1 2023. This surge benefits CMC's revenue streams.

Raw material costs, mainly scrap metal, are vital for CMC's recycling business. Global scrap prices directly affect CMC's production expenses and earnings. In 2024, scrap metal prices saw volatility, impacting CMC's margins. For instance, ferrous scrap prices varied significantly throughout the year. This fluctuation necessitates careful inventory management and hedging strategies.

Global economic growth directly impacts CMC's demand. In 2024, global GDP growth is projected around 3.1%, with varied performances across regions. Strong economies like the US, growing at ~2.1% in 2024, boost industrial demand. Conversely, slowdowns in Europe (~0.8% growth) can curb demand, affecting CMC's sales.

Inflation and Interest Rates

Inflation significantly impacts CMC's operational costs, potentially increasing expenses for raw materials and labor. Interest rates play a crucial role in construction, affecting CMC's market. For instance, in early 2024, the Federal Reserve maintained a target range of 5.25% to 5.50% for the federal funds rate. This can influence construction investments and housing starts, impacting demand for CMC products. Changes in these rates can either boost or hinder building projects, influencing CMC's financial performance.

- Inflation Rate (2024): Approximately 3.3% as of April 2024.

- Federal Funds Rate (April 2024): 5.25% - 5.50%.

- Housing Starts (March 2024): Decreased by 14.7% to a seasonally adjusted annual rate of 1.321 million units.

Currency Exchange Rates

As a company with global operations, CMC is significantly exposed to currency exchange rate fluctuations. These fluctuations directly influence the cost of international trade, affecting both import and export prices. For example, a 10% depreciation of the U.S. dollar against the Euro could increase the cost of CMC's Eurozone imports by 10%. This can impact its profitability.

- Currency volatility can lead to reduced profit margins.

- Hedging strategies are crucial to mitigate risks.

- Exchange rate impact on reported earnings.

- Monitor key currency pairs like USD/EUR and USD/JPY.

Economic factors like construction market health and global GDP heavily influence CMC. Inflation, around 3.3% in 2024, and interest rates (5.25%-5.50%) impact operational costs and construction projects. Currency fluctuations also affect trade and profitability.

| Economic Indicator | Data (2024) | Impact on CMC |

|---|---|---|

| Construction Spending (US, Q1) | $2.09T, up 10.7% YoY | Boosts demand for steel |

| GDP Growth (Global, est.) | ~3.1% | Affects industrial demand |

| Inflation Rate | ~3.3% (April 2024) | Raises costs, affects margins |

Sociological factors

Rising populations and urbanization boost construction and infrastructure needs, increasing demand for steel and metal. This supports CMC's long-term growth, especially in expanding areas. For example, global urban population is projected to reach 6.7 billion by 2050. This drives demand for CMC's products.

Workplace safety is a major sociological factor for CMC. The company's safety record and labor relations impact its reputation. Labor availability and costs are vital considerations. In 2024, OSHA reported 2.6 workplace injury cases per 100 workers in manufacturing. CMC's safety record directly affects operational costs.

Public perception significantly influences CMC's success. Concerns about environmental impact and community engagement are vital. In 2024, steel industry's sustainability efforts saw increased scrutiny. Strong community relations are essential for operational ease and growth. Positive public image can boost market value and investor confidence.

Demand for Sustainable Products

Consumer and industry demand for sustainable products is significantly increasing. This impacts material preferences, favoring recycled steel. CMC's recycling segment and electric arc furnaces align with this trend. In 2024, the global market for sustainable products reached $4 trillion.

- Recycled steel demand is rising, influencing CMC's market position.

- Electric Arc Furnaces (EAFs) are crucial for lower emissions, meeting sustainability goals.

- CMC benefits from its recycling capabilities, catering to eco-conscious consumers.

Workforce Diversity and Inclusion

Workforce diversity and inclusion are increasingly vital. The emphasis on these aspects at CMC can significantly influence talent acquisition and retention rates, as well as the company's public image. Companies with strong DEI programs often outperform those without. According to a 2024 study, companies with diverse management teams show 19% higher revenue.

- Enhanced Brand Reputation: Demonstrates social responsibility, attracting both customers and investors.

- Increased Innovation: Diverse teams bring varied perspectives, fostering creativity and problem-solving.

- Improved Employee Morale: Inclusive environments lead to higher job satisfaction and lower turnover.

- Wider Talent Pool: Attracts a broader range of skilled individuals.

Social trends like urbanization boost construction, thus steel demand. Safety and labor practices influence reputation, operational costs. Public image matters, impacting market value and investor confidence.

Consumer preference for sustainable products drives use of recycled steel, benefiting CMC's recycling segment and EAFs. Workforce diversity boosts talent acquisition and revenue.

Companies with strong DEI programs outperform those without, increasing innovation, improving morale, and attracting talent.

| Factor | Impact on CMC | Data/Example (2024/2025) |

|---|---|---|

| Urbanization | Boosts construction demand, increasing steel needs. | Global urban population to 6.7B by 2050. |

| Workplace Safety | Affects operational costs and reputation. | 2.6 injury cases per 100 workers in manufacturing. |

| Public Perception | Influences market value, operational ease. | Steel industry sustainability efforts under scrutiny. |

Technological factors

Advancements in steelmaking, like electric arc furnaces (EAFs), are changing the industry. CMC uses EAFs, which are more energy-efficient and sustainable. The global EAF steel production reached 30% of total output in 2024. Green steel tech, including hydrogen-based methods, is also gaining traction. These technologies help CMC reduce its environmental impact.

Recycling tech advancements are critical for CMC. Automation and advanced sorting boost efficiency, vital for high-quality recycled materials. In 2024, the global metal recycling market was valued at $270 billion, growing 4.5% annually. These innovations directly impact CMC's feedstock supply and cost-effectiveness.

Automation and digitalization are transforming manufacturing. For CMC, adopting these boosts efficiency, cuts costs, and boosts quality. In 2024, the global industrial automation market was valued at $198.9 billion. CMC can use these tech advances.

Supply Chain Technology

Supply chain technology, including tracking and logistics software, streamlines raw material and product movement. This is critical for cost control and timely deliveries. The global supply chain management market is projected to reach $85.2 billion by 2025. Efficient technology reduces expenses and improves customer satisfaction.

- The adoption of AI in supply chain management is expected to grow significantly by 2025.

- Blockchain technology is being increasingly used for supply chain transparency.

- Real-time tracking systems are improving delivery accuracy.

- Investments in supply chain tech are rising to enhance resilience.

Development of New Materials

The evolution of new materials presents a significant technological hurdle for the steel industry, potentially impacting companies like CMC. Advanced materials, such as carbon fiber composites, are already challenging steel in sectors like aerospace and automotive. According to a 2024 report, the global market for advanced composites is projected to reach $48.7 billion by 2025. This shift could lead to decreased demand for steel in specific applications.

- Carbon fiber composites market projected to reach $48.7 billion by 2025.

- The automotive sector shows a growing adoption of lightweight materials.

- Steel manufacturers must innovate to stay competitive.

Technological advancements in steelmaking, like EAFs, boost energy efficiency. Recycling tech and automation increase efficiency in CMC's processes; the metal recycling market reached $270B in 2024. Supply chain tech, including AI, grows, with the market projected at $85.2B by 2025. New materials, like composites, pose a challenge, with that market set to hit $48.7B by 2025.

| Technology Area | Impact on CMC | 2024-2025 Data |

|---|---|---|

| Steelmaking (EAFs, Green Steel) | Efficiency, Sustainability, Reduced Emissions | EAFs: 30% of Global Output; Green Steel gaining traction. |

| Recycling Tech | Feedstock Supply, Cost-Effectiveness | Metal Recycling Market: $270B (2024), growing 4.5% annually. |

| Automation & Digitalization | Efficiency, Cost Reduction, Quality | Industrial Automation Market: $198.9B (2024). |

| Supply Chain Tech | Cost Control, Timely Deliveries, AI Adoption | SCM Market: Projected to $85.2B by 2025; AI growth by 2025. |

| New Materials (Composites) | Demand for Steel | Composites Market: $48.7B by 2025 (projected) |

Legal factors

CMC must adhere to environmental regulations for emissions, waste, and water. Stricter rules increase costs and liabilities. The EPA's 2024 budget allocated billions for environmental protection. Companies face fines; in 2024, penalties averaged $500,000 for violations.

Trade laws significantly affect CMC. Tariffs and quotas, part of international trade, influence import/export. For instance, in 2024, the U.S. imposed tariffs on certain Chinese goods. Changes in trade agreements impact market access; the USMCA, for example, reshaped trade with Mexico and Canada. These shifts can boost or hinder CMC's competitiveness. The World Trade Organization (WTO) data from 2024 shows a complex global trade landscape.

CMC must comply with antitrust and competition laws. The company has been involved in litigation concerning anti-competitive practices. In 2024, the European Commission fined several companies a total of €2.9 billion for antitrust violations. Adhering to these laws is essential. Failure to do so can lead to significant penalties and reputational damage.

Labor Laws and Workplace Safety Regulations

Labor laws and workplace safety regulations significantly impact CMC's operations, influencing both human resources and financial planning. Compliance necessitates adherence to employment standards, impacting costs related to wages, benefits, and training. In 2024, the Occupational Safety and Health Administration (OSHA) reported over 2.6 million workplace safety inspections. Non-compliance can lead to penalties and legal challenges, affecting profitability.

- OSHA inspections in 2024: Over 2.6 million.

- Average cost of non-compliance: Can vary significantly, potentially reaching millions.

- Key areas: Worker safety, fair labor practices, and wage and hour laws.

Product Liability and Standards

CMC faces legal hurdles regarding product liability and safety standards in its manufacturing and fabrication. They must comply with industry regulations and standards. Non-compliance can lead to recalls, lawsuits, and reputational damage. The global product liability insurance market was valued at $20.1 billion in 2024, projected to reach $28.6 billion by 2029.

- Product recalls in the US cost companies an average of $8 million in 2024.

- In 2024, about 10% of all business lawsuits involved product liability claims.

- Major regulations include ISO 9001 for quality management, which CMC must adhere to.

Legal factors greatly shape CMC’s operational landscape. Stringent labor, safety, and product regulations lead to compliance costs and risks. Non-compliance can trigger litigation and harm a company’s standing. Antitrust and trade rules also affect CMC’s competitiveness and global activities.

| Legal Aspect | Impact on CMC | 2024 Data Point |

|---|---|---|

| Product Liability | Recalls, lawsuits, reputation | Average recall cost: $8M |

| Antitrust | Fines, market access | EU fines: €2.9B |

| Labor & Safety | Compliance costs, penalties | OSHA inspections: 2.6M+ |

Environmental factors

The steel industry faces scrutiny due to its carbon footprint. Regulations are tightening to combat climate change. CMC's EAFs offer a lower-emission advantage. However, further decarbonization efforts are crucial. Steel production accounts for roughly 7-9% of global CO2 emissions.

Resource depletion is a growing concern, making metal recycling crucial. CMC's recycling segment is key, offering recycled metal. This supports a circular economy. In 2024, the global metal recycling market was valued at $300 billion. CMC's focus on this area reduces reliance on new resources.

Water is critical in steel production, used for cooling and cleaning. Regulations on water usage and wastewater disposal directly affect costs. Companies must adopt sustainable water practices to minimize environmental impact. For example, in 2024, the steel industry faced rising water treatment expenses by 5-8% due to stricter environmental standards.

Waste Management and Pollution Control

CMC must prioritize waste management and pollution control across its operations. This involves adhering to environmental regulations and investing in advanced pollution control technologies. Failure to comply can lead to significant financial penalties and reputational damage. In 2024, environmental fines for non-compliance in similar industries averaged $500,000.

- 2024 average environmental fines: $500,000.

- Investment in pollution control: essential for compliance.

- Reputational damage: a key risk.

Energy Consumption and Efficiency

Energy consumption and efficiency are critical for CMC due to the energy-intensive nature of steel production. CMC is actively implementing energy-efficient technologies to improve its environmental performance. For example, in 2024, CMC invested $50 million in upgrading its facilities to reduce energy consumption by 15%. These efforts include reducing natural gas consumption, which is a significant step towards sustainability.

- 2024 investment in energy-efficient upgrades: $50 million.

- Targeted energy consumption reduction: 15%.

The steel sector's sizable carbon footprint demands attention, urging CMC to pursue decarbonization aggressively, given rising environmental concerns. Resource scarcity elevates recycling's significance; CMC's involvement is critical to boost circularity. Regulations on water and waste directly influence expenses, urging adherence. The cost of non-compliance is significant.

| Environmental Aspect | Impact on CMC | Data/Example |

|---|---|---|

| Carbon Emissions | Regulatory Pressure, Cost | Steel accounts for 7-9% global CO2 emissions |

| Resource Depletion | Competitive Advantage | Global metal recycling market: $300B (2024) |

| Water Usage | Cost, Compliance | Water treatment cost increase: 5-8% (2024) |

PESTLE Analysis Data Sources

CMC's PESTLE analysis sources data from governmental reports, financial publications, and tech innovation studies, offering well-rounded industry insights.