DMG Mori PESTLE Analysis

Fully Editable

Tailor To Your Needs In Excel Or Sheets

Professional Design

Trusted, Industry-Standard Templates

Pre-Built

For Quick And Efficient Use

No Expertise Is Needed

Easy To Follow

DMG Mori Bundle

What is included in the product

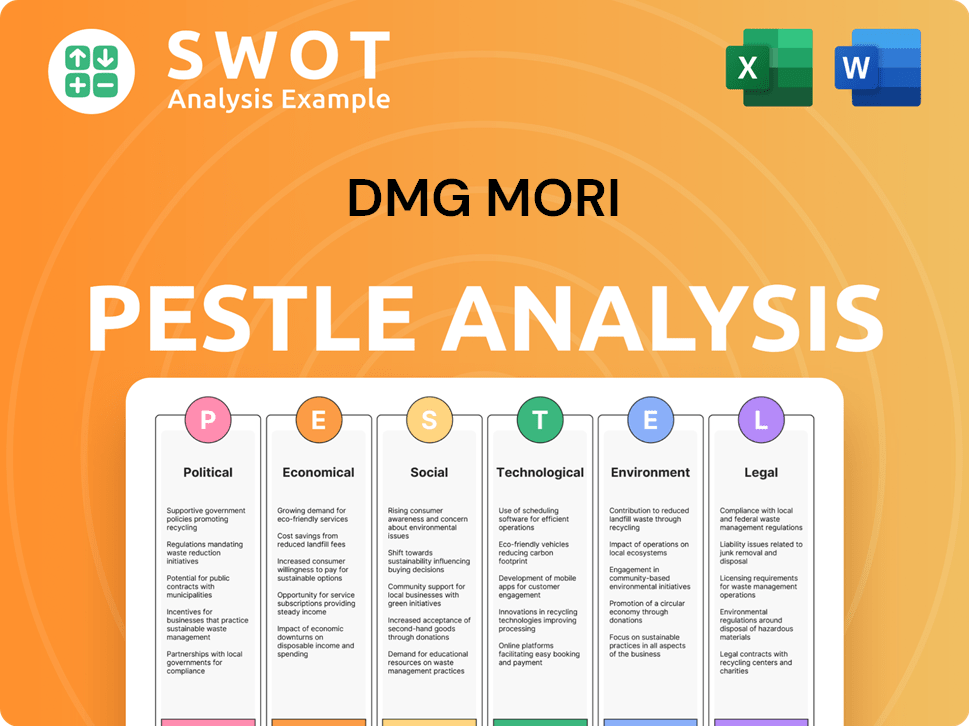

A PESTLE analysis exploring how macro-environmental factors impact DMG Mori.

Aids strategic decision-making, synthesizing complex market insights for faster, data-driven decisions.

Preview Before You Purchase

DMG Mori PESTLE Analysis

The preview you see provides an accurate view of the DMG Mori PESTLE analysis. It contains the exact details and formatting. The file's content and organization mirror what you will get. Download it instantly after purchase; it is a complete analysis.

PESTLE Analysis Template

Navigate DMG Mori's future with our focused PESTLE Analysis. We explore the political landscape impacting the company's strategy. Understand economic shifts and their effects on the firm's performance. Analyze how technological advancements and social trends are shaping DMG Mori's outlook. Discover environmental considerations and legal impacts crucial for success. Gain actionable insights and strategic foresight instantly with the full version download.

Political factors

Government policies and regulations are crucial for DMG Mori. Environmental protection standards and worker safety regulations directly affect manufacturing processes. Compliance is vital to avoid penalties; this can impact production costs. For instance, in 2024, stricter emissions rules in the EU increased manufacturing expenses by 5%.

Trade agreements and tariffs significantly influence DMG Mori's operations. For example, the U.S. imposed tariffs on steel and aluminum in 2018, raising input costs. The machine tool sector's global nature makes it vulnerable to these changes. As of late 2024, monitoring evolving trade policies is crucial for profitability.

Geopolitical instability poses significant risks for DMG Mori. Tensions can disrupt supply chains, impacting production. For instance, the Russia-Ukraine war has already affected global manufacturing, including machine tools. Such instability reduces demand in affected regions. In 2024, geopolitical events heavily influenced international trade and investment decisions.

Investment Incentives and Support

Government incentives significantly influence investment decisions in the manufacturing sector, especially for companies like DMG Mori. Support for technological advancements, such as tax credits for R&D, encourages investment in new machinery and innovative processes. For instance, Germany's "Future Fund" allocated €10 billion to support future technologies and R&D. These incentives boost growth within the machine tool sector. Furthermore, they enhance competitiveness through innovation.

- Germany's "Future Fund" allocated €10 billion.

- Tax credits for R&D.

- Support for new machinery.

- Boost competitiveness through innovation.

Political Risk in Operating Regions

Operating internationally subjects DMG Mori to political risks. These risks include potential asset nationalization, as seen with the Russia subsidiary. The company's 2023 annual report noted a loss due to the Russia exit. Political instability significantly affects supply chains and market access.

- Political risk assessment is crucial for international operations.

- DMG Mori's experience in Russia highlights financial exposure.

- Geopolitical events can disrupt manufacturing and sales.

- Diversification across regions can mitigate political risks.

Political factors deeply impact DMG Mori's operations and strategy. Government regulations, like emissions standards, influence production costs; a 5% increase occurred in 2024 due to EU rules. Trade agreements and tariffs are critical; tariffs on steel can raise input expenses, affecting profitability. Geopolitical instability also poses supply chain risks, demonstrated by impacts from the Russia-Ukraine war, influencing demand. In addition, government incentives, such as R&D tax credits and initiatives like Germany's "Future Fund" (€10 billion), significantly encourage investment in new technologies. Operating internationally, DMG Mori must assess political risks. Asset nationalization poses risks, evident in the 2023 financial outcomes.

| Factor | Impact | Example (2024/2025) |

|---|---|---|

| Regulations | Increased Costs | 5% rise in EU emissions-related manufacturing expenses. |

| Trade | Supply Chain disruptions & Costs | Tariffs increasing steel prices affect input costs. |

| Geopolitics | Market access reduction | Impact from Russia-Ukraine war reducing demand |

Economic factors

Global economic conditions significantly impact DMG Mori's performance. Manufacturing activity declines in economic downturns, reducing machine tool demand. For example, in 2023, global manufacturing PMI fluctuated, reflecting economic uncertainties. Conversely, economic growth boosts investment in machinery.

Inflation significantly influences DMG Mori's operational costs, including materials and labor. Rising interest rates increase borrowing costs for both the company and its customers. As of early 2024, Eurozone inflation hovered around 2.6%, impacting manufacturing costs. Increased interest rates can potentially reduce customer investment in capital goods.

Currency exchange rate volatility significantly influences DMG Mori's financial performance, especially in its global operations. Fluctuations directly affect the cost of raw materials, components, and finished goods sold across different markets. For instance, a stronger euro (EUR) against the Japanese yen (JPY) could make DMG Mori's products more expensive in Japan. In 2024, the EUR/JPY exchange rate saw variations, impacting the company's profitability margins.

Raw Material Costs

Raw material costs significantly influence DMG Mori's production costs and profit margins, particularly for steel, aluminum, and other metals used in machine tool manufacturing. Fluctuations in global commodity prices, such as those seen in 2024, directly affect the company's expenses. The availability of these materials is also crucial, with supply chain disruptions potentially increasing costs and delaying production schedules.

- Steel prices increased by approximately 15% in the first half of 2024 due to demand and supply chain issues.

- Aluminum prices have shown volatility, with a 10% swing in the past year.

- DMG Mori's cost of goods sold (COGS) is heavily influenced by these raw material prices.

Labor Costs and Availability

Labor costs and the availability of skilled workers are pivotal for DMG Mori. Rising labor costs, especially in developed economies, can squeeze profit margins. Shortages in skilled labor, such as CNC machinists, can also hinder production capabilities.

For example, in Germany, where DMG Mori has significant operations, the average manufacturing hourly labor cost was about 44 EUR in 2024, according to Eurostat data. This is a key factor in DMG Mori's operational strategy.

Consider these points:

- Germany's high labor costs necessitate efficiency improvements.

- Skills shortages drive automation investments.

- DMG Mori may consider locating production in regions with lower labor costs.

- Training programs are crucial to ensure a skilled workforce.

Economic factors are critical for DMG Mori. Fluctuating global manufacturing, for instance, caused volatility in the sector. The increase in steel prices in early 2024 by 15% influenced production expenses, affecting profit margins. Labor expenses in Germany averaged about 44 EUR per hour, impacting operational strategy.

| Economic Factor | Impact on DMG Mori | Data/Example (2024) | |

|---|---|---|---|

| Manufacturing Activity | Affects demand for machine tools | Global PMI fluctuated in 2023/2024 | |

| Inflation | Increases costs | Eurozone inflation ~2.6% early 2024 | |

| Exchange Rates | Affects profitability | EUR/JPY rate varied |

Sociological factors

The availability of a skilled workforce directly affects DMG Mori's ability to function. Shifts in education and vocational training attitudes are critical. Germany's vocational training model, for example, is a strength. In 2024, Germany had 1.2 million apprentices. Changes in these areas can impact the company's talent pool and operational efficiency.

An aging workforce, particularly in countries like Germany and Japan, poses challenges. DMG Mori might face a shortage of skilled labor. This could necessitate increased investment in training programs and automation technologies to maintain productivity levels. For example, Germany's workforce is projected to shrink by millions by 2030. This could lead to higher labor costs and potential skill gaps.

Societal norms and government rules on workplace safety directly affect DMG Mori's operations. Investing in safety measures is a must for employee well-being. For example, in 2024, the global market for industrial safety equipment reached $75 billion, showing the industry's importance.

Consumer Demand and Preferences

Consumer preferences significantly shape the demand for manufactured goods, directly impacting DMG Mori. Shifts in automotive trends, like the rise of electric vehicles, influence the machine tools needed for production. Aerospace advancements also drive demand for specialized machinery. For example, the global automotive sector is projected to spend $300 billion on EVs by 2025, increasing demand for precision manufacturing.

- Automotive EV spending: $300B by 2025.

- Aerospace growth: 5% annually.

Public Perception of Manufacturing

Public perception significantly impacts manufacturing, including DMG Mori. A favorable view attracts skilled workers and investment, crucial for innovation and expansion. Conversely, a negative image can hinder growth. Manufacturing's image is evolving, with a focus on sustainability and technological advancement. This shift is pivotal for attracting the next generation of talent.

- In 2024, 68% of U.S. adults viewed manufacturing positively.

- Manufacturing employment in the U.S. reached 13 million in early 2024.

- Investments in advanced manufacturing technologies increased by 15% in 2024.

- Around 70% of millennials see manufacturing as a viable career path.

Societal values concerning work-life balance and remote work impact DMG Mori's operations. Labor force dynamics shift with younger generations prioritizing flexibility. By mid-2024, 60% of firms adopted hybrid models.

| Sociological Factor | Impact on DMG Mori | 2024/2025 Data |

|---|---|---|

| Work-life balance | Attract and retain talent, affect productivity | Hybrid work adoption: 60% of companies |

| Diversity and Inclusion | Shape company culture and reputation | D&I spending: Increased by 10% YOY |

| Public perception | Affect brand image and investor interest | Positive manufacturing view by 68% in the U.S. |

Technological factors

Advancements in automation and robotics are reshaping manufacturing, boosting efficiency and accuracy. DMG Mori needs to incorporate these technologies to stay competitive. The global industrial robotics market is projected to reach $81.6 billion by 2025. This growth highlights the need for machine tool makers to adapt. In 2024, automation spending increased by 12% in the manufacturing sector.

New materials and machining processes are pivotal. DMG Mori must adapt to work with advanced materials like composites. This necessitates constant technological advancements. In 2024, the global advanced materials market was valued at $86.5 billion, showing a 7% annual growth.

Digitalization, IoT, and AI are transforming manufacturing (Industry 4.0). DMG Mori's 'Machining Transformation (MX)' strategy embraces this. The global smart factory market is projected to reach $110.6 billion by 2024. Connected machines enhance efficiency and data-driven decision-making.

Software and Control Systems

Software and control systems are fundamental to DMG Mori's CNC machines, enhancing precision and automation capabilities. Recent advancements include AI-driven optimization and predictive maintenance, improving machine efficiency. The global CNC machine market, valued at $78.4 billion in 2023, is projected to reach $105.2 billion by 2030. These technologies drive operational improvements, boosting productivity and reducing downtime.

- AI-driven optimization enhances machine efficiency.

- Predictive maintenance reduces downtime.

- The CNC machine market is growing.

- Automation capabilities are improving.

Additive Manufacturing (3D Printing)

Additive manufacturing, like 3D printing, presents both opportunities and challenges for DMG Mori. The rise of 3D printing could either complement or compete with DMG Mori's subtractive manufacturing. Machine tool companies need to adapt to integrate or collaborate with 3D printing technologies. The global 3D printing market is projected to reach $55.8 billion by 2027, a significant growth area.

- Market growth: 3D printing market expected to reach $55.8B by 2027.

- Adaptation: Machine tool companies must integrate or collaborate with 3D printing.

DMG Mori faces technological shifts like automation, robotics, and advanced materials. The industrial robotics market is poised to hit $81.6 billion by 2025, driving the need for adaptation. Digitalization and AI are transforming manufacturing; the smart factory market is set to reach $110.6 billion by 2024. The CNC market is projected to hit $105.2B by 2030, emphasizing efficiency.

| Technology | Market Size/Growth | Implication for DMG Mori |

|---|---|---|

| Automation & Robotics | $81.6B by 2025 (Industrial Robotics) | Integrate to boost efficiency and competitiveness |

| Advanced Materials | 7% annual growth in 2024 ($86.5B) | Adapt to work with composites and stay innovative |

| Digitalization & AI | $110.6B by 2024 (Smart Factory) | Embrace Industry 4.0, focus on data-driven decisions |

| 3D Printing | $55.8B by 2027 (3D Printing Market) | Integrate or collaborate with 3D printing technologies. |

Legal factors

DMG Mori must comply with machinery directives and safety standards to sell its products. These regulations ensure user and environmental safety. In the EU, compliance with the Machinery Directive 2006/42/EC is essential. Non-compliance can lead to significant fines and market restrictions, impacting revenue. For example, a 2024 study showed non-compliant firms faced up to 10% revenue loss.

DMG Mori, as a global manufacturer, must navigate complex intellectual property laws. Securing patents for innovative technologies and processes is essential to protect its competitive edge. In 2024, the company invested a significant amount in R&D, leading to several patent filings. Failure to respect others' IP rights could result in costly legal battles and damage the company's reputation. For example, in 2023, IP infringement lawsuits cost the manufacturing sector billions globally.

DMG Mori must comply with labor laws, impacting costs and HR. In Germany, the minimum wage is EUR 12.41/hour (2024). Workplace safety and working hour regulations also affect operations. Non-compliance can lead to fines and legal issues, increasing expenses.

Environmental Regulations

DMG Mori, as a manufacturer, faces stringent environmental regulations concerning emissions, waste management, and hazardous substance use. Compliance necessitates significant investments in advanced, eco-friendly technologies and operational adjustments. For instance, in 2024, the company allocated approximately €12 million towards improving its environmental footprint, including waste recycling and emissions reduction. These regulations can impact production costs and operational efficiency.

- Investments in cleaner technologies and processes are essential.

- Compliance costs can affect profitability.

- Regulations vary by region, adding complexity.

- Environmental performance is increasingly important to stakeholders.

Product Liability Laws

Product liability laws are a crucial legal factor for DMG Mori, as manufacturers can be held accountable for defects in their products that lead to harm or damage. This means DMG Mori must prioritize product safety and quality to minimize legal exposure. Recent data from 2024 indicates that product liability lawsuits cost businesses billions annually. These lawsuits often involve complex machinery, increasing the potential for significant financial repercussions for DMG Mori.

- In 2024, product liability settlements averaged $500,000 to $1 million per case.

- Compliance with international safety standards, such as ISO 9001, is essential.

- Regular product testing and rigorous quality control are vital to avoid liability.

Legal factors for DMG Mori involve stringent compliance across various domains, impacting operations and costs. Machinery directives and safety standards necessitate ongoing adherence to protect user safety, and the firm must allocate substantial resources for maintaining it. Protecting intellectual property via patent filings and respecting others’ rights are vital to avoid significant financial damage. Non-compliance could cause up to 10% of revenue loss.

| Area | Legal Concern | Financial Impact (2024) |

|---|---|---|

| Product Liability | Defective products | Settlements averaging $500K-$1M/case |

| IP Infringement | Patent violations | Billions in global sector costs |

| Environmental | Emissions/Waste | €12M investment for improvements |

Environmental factors

Manufacturing processes, especially the use phase of machine tools, consume substantial energy. Pressure grows to boost energy efficiency and cut environmental impact. In 2024, the manufacturing sector accounted for roughly 30% of global energy consumption, according to the IEA. DMG Mori is investing in energy-efficient technologies.

DMG Mori's manufacturing generates waste, demanding compliance with environmental regulations. In 2024, global waste management spending reached $2.1 trillion, growing annually. Companies face rising costs for waste disposal and potential penalties for non-compliance. Effective waste management directly impacts profitability and sustainability.

Resource depletion and material sourcing are critical environmental factors. DMG Mori faces pressure to adopt sustainable practices. Demand for recycled materials is rising; in 2024, the market for recycled plastics grew by 6%. Circular economy principles are gaining traction, impacting supply chains.

Climate Change and Carbon Emissions

The manufacturing sector significantly contributes to global carbon emissions, pressuring companies like DMG Mori to adopt sustainable practices. In 2023, the industrial sector accounted for approximately 24% of global greenhouse gas emissions. DMG Mori must reduce its carbon footprint to comply with environmental regulations and meet stakeholder expectations. This shift involves investing in energy-efficient technologies and renewable energy sources.

- Industrial sector emissions accounted for ~24% of global GHG emissions in 2023.

- Companies face increasing pressure to reduce carbon footprints.

- Investment in sustainable manufacturing is crucial.

Impact of Manufacturing Environment on Precision

Environmental factors significantly influence manufacturing precision. Temperature and humidity fluctuations in facilities can affect machining accuracy. Maintaining stable conditions is crucial for consistent product quality. DMG Mori invests in climate control to mitigate these environmental impacts.

- In 2024, the global market for precision manufacturing equipment was valued at approximately $150 billion.

- Companies like DMG Mori allocate around 5-7% of their operational budget to environmental control systems.

- A 1°C temperature change can result in a 0.001mm deviation in precision machining.

DMG Mori faces intense environmental pressure, highlighted by the industrial sector's ~24% of 2023 global GHG emissions. Energy efficiency and waste reduction are critical, with the waste management sector valued at $2.1 trillion in 2024. Sustainable practices and circular economy principles are gaining traction impacting supply chains.

| Factor | Impact | Data |

|---|---|---|

| Energy Consumption | Efficiency requirements | Manufacturing = ~30% global energy consumption (2024 IEA) |

| Waste Management | Cost, compliance | Waste management spending $2.1T (2024, growing) |

| Resource Use | Sustainable sourcing | Recycled plastics market grew by 6% (2024) |

PESTLE Analysis Data Sources

This analysis uses data from governmental agencies, economic databases, and industry reports for comprehensive macro-environmental insights. Information spans global markets and local factors for accurate DMG Mori analysis.